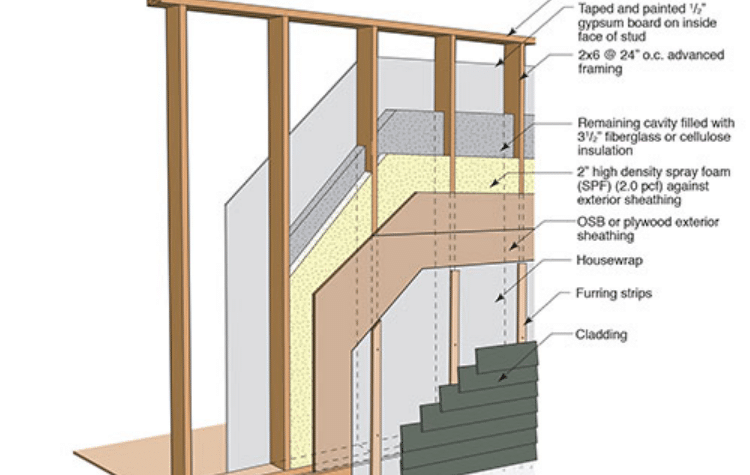

The flash and fill insulation is a standard way of insulating homes across the U.S.. It is a hybrid form of insulation because it is a combination of 2 types of insulation; closed cell foam insulation and blown-in insulation into one efficient wall assembly. The 2 lb. closed cell spray foam is sprayed against the inside of the sheathing in various depths from 0.25” inch to 3” deep then the remaining chamber area is filled with a blown in insulation as show in the main illustration. The EcoSmart™ Stud upgrade picture below shows how the EcoSmart™ Stud interacts with and improves this hybrid insulation style.

How EcoSmart™ Studs Improve Flash and Fill Insulation

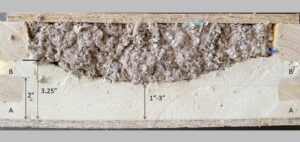

The EcoSmart™ Stud improves the flash and fill insulation method by allowing the spray foam to flow through thermal break points (identified as points A & B)rather than being stopped by a solid stud. This accomplishes two things. Thermal breaks and it completely embeds the EcoSmart™ Studs in the spray foam which is 100% attached to the sheathing. Even with just point A filled with spray foam the PLF rating is above the racking requirements for most high wind and seismic areas with just a hybrid 6/12 nailing pattern and 7/16 OSB.

The depth and the mix of the 2 insulation types; closed cell foam insulation and blown-in insulation, as well as the type of EcoSmart™ Stud used, determines the U-value ands effective R-value of the assembly.

With the 2×6 EcoSmart™ Stud and the 1” minimum 2 lb. spray foam required for the installation the effective insulation value of the exterior wall assembly will meet the U-Value requirement for the 2021/2024 Energy Code. The wall assembly is also sealed tight against air infiltration along the entire length of the exterior walls for the building including the corners.

The 2×8 EcoSmart™ Stud has all the same structural benefits of having the sheathing glued and nailed to the framing. With the extra depth for insulation the U-value and effective R-value for any insulation mix of 2 lb. spray foam and blown in insulation far exceed the requirements for the 2021/2024 Energy code.

What Is the R Value of Spray Foam Insulation?

One of the biggest advantages of closed cell spray foam insulation is its high R-value. For 2 lb. closed cell foam, the R-value is generally R-6 to R-7 per inch, significantly outperforming standard fiberglass batts. In a flash and fill application, combining spray foam with blown-in insulation results in an effective R-value that far exceeds code requirements.

How to Spray Foam Insulation

Here’s a simplified process on how to spray foam insulation as part of a flash and fill system:

- Prep the wall cavity – Make sure it’s clean, dry, and ready.

Apply spray foam – Spray closed cell foam insulation at 1–3” depth to the interior sheathing. - Let it dry (more below).

- Fill the remaining cavity – Use blown-in insulation to complete the chamber.

- Inspect for air gaps – Ensure full coverage and sealing.

This approach creates a high-performance, energy-efficient wall assembly that’s ideal for net zero homes.

Ready to Build Better?

Whether you’re a builder, architect, or homeowner, using the EcoSmart™ Studs and flash and fill insulation can help your next project exceed energy code standards.

For more details, see our Resources tab for installation instructions, TER documentation, and a downloadable PDF on Energy Design Criteria for exterior walls.

See our resources tab for installation instructions, TER link, and for the downloadable PDF for Energy Design Criteria of exterior walls. There is also a blog post going over this information for Energy Star Zero Energy Ready Homes.