By simply removing material, we see benefits immediately. These start at the saw mill.

Weight

The EcoSmart Stud removes between 4-6 lbs of wood per stud, reducing the weight of the stud.

CREATING MATERIAL FOR ADDITIONAL USES

One lumber shipment can create 5,000,000 lbs of wood pulp to make other wood products. That saves harvesting 1000+ fewer trees to make those products.

The benefits continue at every step of supply-chain transportation.

Reduced Weight

One 75 car lumber train loaded with 2×6-8 EcoSmart™ studs is potentially 5,000,000 lbs. lighter.

Fuel & CO2 Emissions Savings

EcoSmart™ Studs have about one-third less weight than traditional studs. This means lower fuel consumption and CO2 emissions in all transportation.

The EcoSmart™ Stud is a 1-to-1 replacement for a standard construction stud

It functions like a normal solid stud, it’s just far better. That means it fits right into standard building practices.

The reduced weight is easier from framers to handle as they build exterior walls. Additionally, the areas of removed material can be used to run electrical wiring and conduit without additional drilling. Less clean up after trades.

Reduced callback risk related to exterior wall construction compared to ridged foam, lowering the potential of additional cost.

The biggest impact comes from better insulated homes.

CREATING A MORE EFFICIENT HOME

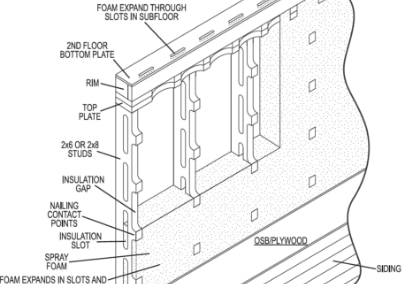

The magic of the EcoSmart™ Stud is what’s not there—it’s slots and gaps. These holes allow higher-value insulating material, such as foam, to disperse more broadly inside exterior walls.

SAVING ENERGY AND MONEY

With insulation filing more space instead of wood (which doesn’t insulate as well) the building stays at the desired temperature longer, lowering energy bills and CO2 emissions.

Cost Benefits

Construction

The EcoSmart Stud weighs less than a solid 2×6 so it’s easier to move around the construction site by the framers. Plus it’s predrilled for the electrician to run wires!

Insulation

When closed cell spray is used in the wall assembly the foam seals the cavity which means no air flow through gaps in the sheathing. It also gives the EcoSmart Stud the highest potential insulation value.

Environment

The lighter weight of the EcoSmart stud means less fuel used in shipping. Less fuel used means less CO2 going into the atmosphere. The wood pulp removed from milling the EcoSmart stud becomes other products lowering the pressure on forests.

Composite Wall System:

Changing out the 1-2” of ridged foam to 1-2” of spray foam applied to the interior of the sheathing and combining with ESS many things are accomplished by this one simple change:

Any builder can build an ESS wall successfully compared to ridged foam.

Equivalent or better effective insulation values at far less cost.

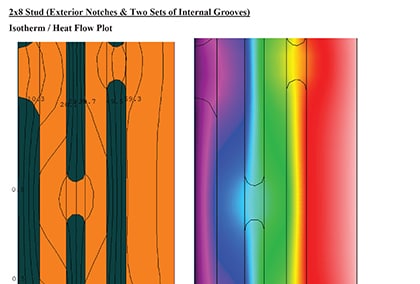

ESS walls 30-110+% increase in actual wall insulation

Increased Racking strength over Ridged foam walls.

Less chance of structural compromise.

Air sealed walls, less chance of air leaks compared to ridged foam

Walls can dry to inside and outside of cavity.