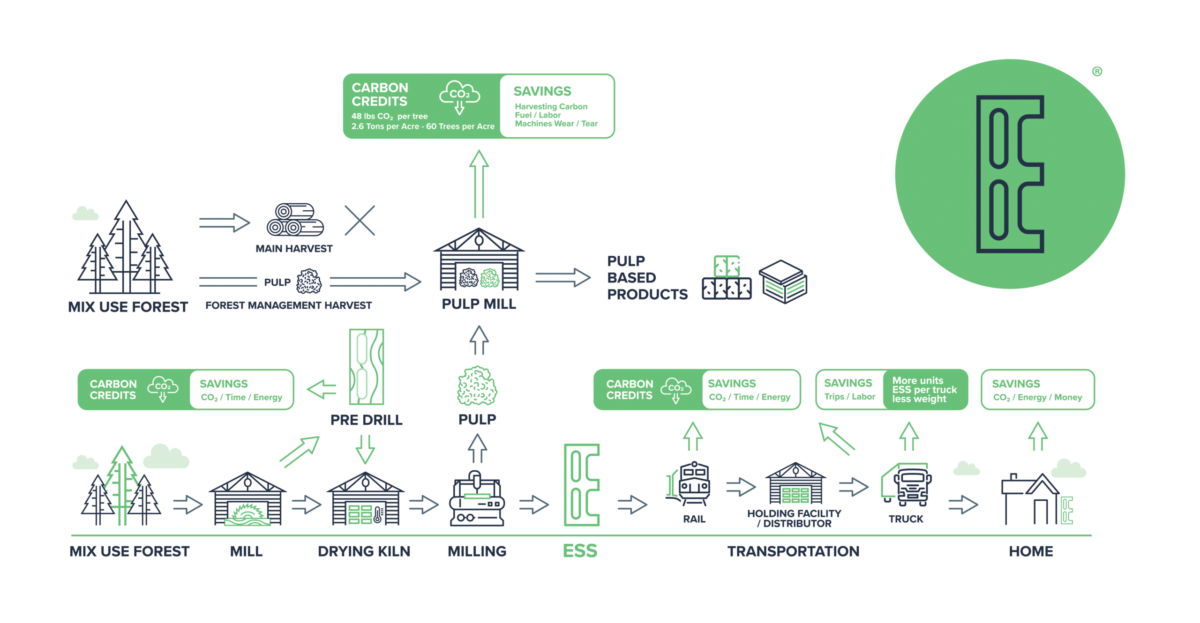

Most people are familiar with Operational Carbon, which is the CO2 emissions caused by burning fossil fuels. In the feature picture, Operational Carbon is represented by the picture of the Home in the lower right corner. Embodied Carbon gets a little more complicated, and that is represented by everything to the left of the drawing of the Home.

Embodied Carbon refers to the carbon emissions arising from the manufacturing, transportation, installation, maintenance, and disposal of a product or building. It is a crucial factor in determining the environmental impact of construction materials. The EcoSmart™ Stud is a Department of Energy Impel 2023 Cohort. The Impel program is focused on removing both Operational and Embodied Carbon from Residential construction.

As a Cohort, we presented the EcoSmart™ Stud and its ability to reduce Embodied and Operational Carbon. The featured image for this article was first used for this presentation. We were the only 2023 Cohort to be able to give calculations for saving carbon emissions in the construction supply chain. No new distribution system is needed since the EcoSmart™ Stud uses the existing lumber distribution system.

The EcoSmart™ Stud excels in reducing Operational Carbon emissions for homes and Embodied Carbon through the entire construction supply chain back to the mill, including forest harvesting.

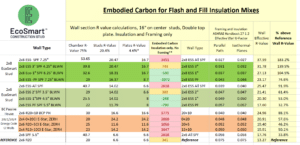

Embodied Carbon is where most Continuous Insulation products have a problem. Since most rigid insulation panels are foam-based products, they have a very high Embodied Carbon rating because they are oil-based products. The graph below focuses on Embodied Carbon for the insulation products for different wall assemblies. The orange section is the 2021/2024 Energy Code CI wall assemblies. The dark green and lighter green are EcoSmart™ Stud wall assemblies. No Embodied Carbon for framing is taken into account for these Embodied Carbon calculations; this is just for insulation products.

The Embodied Carbon calculations are all based on Co2e/m2 figures from The City of Nelson Materials Carbon Emission Guide PDF. The guide is one of the best we have seen because it is simple to understand and use.

When looking at the Embodied Carbon calculations for Flash and Fill insulation mixes, several of the EcoSmart™ Stud wall assemblies have negative Co2e/m2 numbers for Embodied Carbon, indicating the wall section is sequestering Carbon. That is because of the mix of 2 lb. closed cell spray foam (positive) rating and the (negative) blown-in cellulose insulation. The balance point for EcoSmart™ Stud wall assemblies is between 1-2″ of SPF, depending on the use of a 2×6 or 2×8 EcoSmart™ Stud. Using the 2×8 EcoSmart™ stud and picture framing the wall cavities, filling the chamber with cellulose insulation accomplishes the U-factor of less than U-0.045 required for the Energy Star ZERH program. The bonus is a significant carbon sink exterior wall assembly. Even the EcoSmart™ Stud wall assemblies with a positive rating have a much higher effective insulation rating.

EcoSmart™ Stud 1″ Chamber EcoSmart™ Stud picture frame Top view SPF & cellulose mix

By contrast, the 2021/2024 Energy Code CI wall assemblies have no negative numbers, they are all considerably positive. That is because 4’x8′ rigid XPS (extruded polystyrene) foam panels are among the most popular rigid insulation panels used due to cost and an R-value of R5 per inch for continuous insulation wall assemblies. While the old XPS formula, rated at 4937 kg Co2e/m2, has been retired, the new XPS formula still has a 715 kg Co2e/m2 carbon emissions rating.

While an 85% decrease in kg of Co2e/m2 is impressive, as a lot of trainers like to talk about when discussing Continuous Insulation wall assemblies, it’s still the highest Embodied Carbon rating of all the rigid insulation panels. EPS foam and Polyisocyanurate rigid panels have a lower kg Co2e/m2 rating but are still positive numbers. The thicker the continuous insulation is, the higher the embodied Carbon. Considering how much of these products would need installation across the country, the amount of Embodied Carbon involved would add up.

Wood fiber rigid insulation panels are far better for the environment; they all have negative Co2e/m2 ratings. Unfortunately, due to their much higher price point, they are selected for a very small number of installations.

The other issue for Continuous Insulation is insulation waste; 4×8 rigid panel must be cut to fit, always leaving excess waste that needs to be recycled (best case) or thrown in a dumpster (typical). Gathering cut panels for recycling or tossing them in the dumpster takes labor. Once in the dumpster, the landfill is the next stop.

Leftover rigid XPS foam panel pieces

The Flash and Fill style of insulation used for the EcoSmart™ Stud wall assembly has little waste. The spray foam molds into the EcoSmart™ Studs and chamber, the blown-in cellulose can be swept up and constantly blown back into the chamber. Any excess cellulose from the exterior wall insulation install can be added to the ceiling insulation install. This efficient process ensures minimal insulation waste, providing a practical and sustainable solution.

Then there are the studs themselves. EcoSmart™ Studs and solid 2×6 and 2×8 studs sequester CO2. However, the solid studs have a higher embodied carbon rating due to the CO2 expended in harvesting, producing, and getting them to the job site. The EcoSmart™ splits the production CO2 because of the 2 separate products, the EcoSmart™ Studs and wood removed from the solid stud which is a separate product. Then, there is the lighter shipping weight through the supply chain to the job site. Rail shipping is lighter weight per rail car, semi truck shipping is more interesting. Shipping via semi-truck, the EcoSmart Studs hit the volume limit of the flatbed, whereas the solid studs hit the truck’s shipping weight limit and even with more units on the flatbed the EcoSmart™ Stud units are still lighter then the fewer units of solid studs! Far fewer semi trucks are needed to ship EcoSmart™ Studs.

Less Embodied Carbon and less insulation waste going to landfills. The EcoSmart™ Stud wall assemblies are not just a choice, they are the inspiring choice for a more sustainable future with significantly lower embodied carbon and carbon emissions through innovative construction practices.