The Loon Lake build is moving along quickly! First-floor framing is complete, and second-floor framing has begun. There is a slight plan change, so part of the second floor is framed, while the changed part of the plan is awaiting the AHJ’s sign-off. But, we still have great pictures to look at!

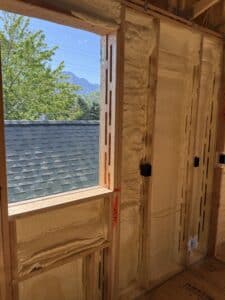

Some of you who have been following the EcoSmart Stud may have noticed a couple of different studs in these pictures. We take feedback from builders very seriously, as our board members almost all have backgrounds in building. You can see the EcoSmart Jack/trimmer stud being used around the window rough opening.

2×6 EcoSmart Jack/trimmer stud

The EcoSmart Jack/trimmer stud has the needed depth for the window nailing flange attachment. It also features more solid lumber for trimming, suitable for various header sizes. There is less lumber waste using a specific stud for this location.

Slotted 2×4’s, speed up installs

Next, notice the interior 2x4s with slots in them. The builder requested the slotted 2x4s to help speed up the electrical, plumbing, and low-voltage installation. After the build, we’ll review how things went and consider making the stud an official EcoSmart Stud!

2×8 EcoSmart Perimeter Studs and Jack/trimmer Studs

The 2×8 EcoSmart Perimeter stud is shown here at the corner. This front wall features all 2×8 framing.The Loon Lake build is a mix of 2×6 and 2×8 EcoSmart studs. With the 2″ flash and fill mix of insulation, the home will be incredibly air tight, structurally reinforced, and super insulated.

Precedent Build used the 2×8 EcoSmart Perimeter Stud in the construction of the Salt Lake City, Utah, display wall. The insulation company installed the spray foam before pictures got taken of the open framing. I did take photos of the 2×8 Jack/trimmer stud in the window cavity of the Utah build.

For all Passive House enthusiasts, you can see how it’s possible to maintain a greater thermal break in the framing with the 2×8 EcoSmart Studs. When using a 2″ Flash and Fill insulation mix, the effective wall insulation value exceeds British Columbia Passive House requirements. Moreover, the embodied carbon of the Flash and Fill insulation products is far lower when natural fiber blown-in insulation, such as cellulose or hemp, is used for the Fill. Compared to ridged foam CI panels, there is very little insulation waste to go in a landfill and the embodied carbon for the wall system is significantly lower.

By choosing these products, you are not just meeting standards, but also actively contributing to a carbon-neutral environment, empowering you to make a significant impact.