Wall framing with built in thermal breaks is the solution for builders across the country to build more energy efficient residential housing at a lower cost.

The goal in the US is for all new residential housing to be Zero Energy Ready by 2030 and Net Zero by 2050. 2030 is only 5 years from now and we aren’t even close to this goal! Last year the total number of single family homes built to Energy Star Zero Energy Ready standards, Passive House, and Phius Passive House was less than 4% of all new housing starts.

This is because it’s extremely expensive and complicated to put ridged insulation panels over the entire outer shell of a home. This is known as Continuous Insulation (CI), or Exterior Continuous Insulation (ECI), and XO Foam (this one is builder slang for CI or ECI).

Solving the Problem, Move the Thermal Break into the Wall Stud

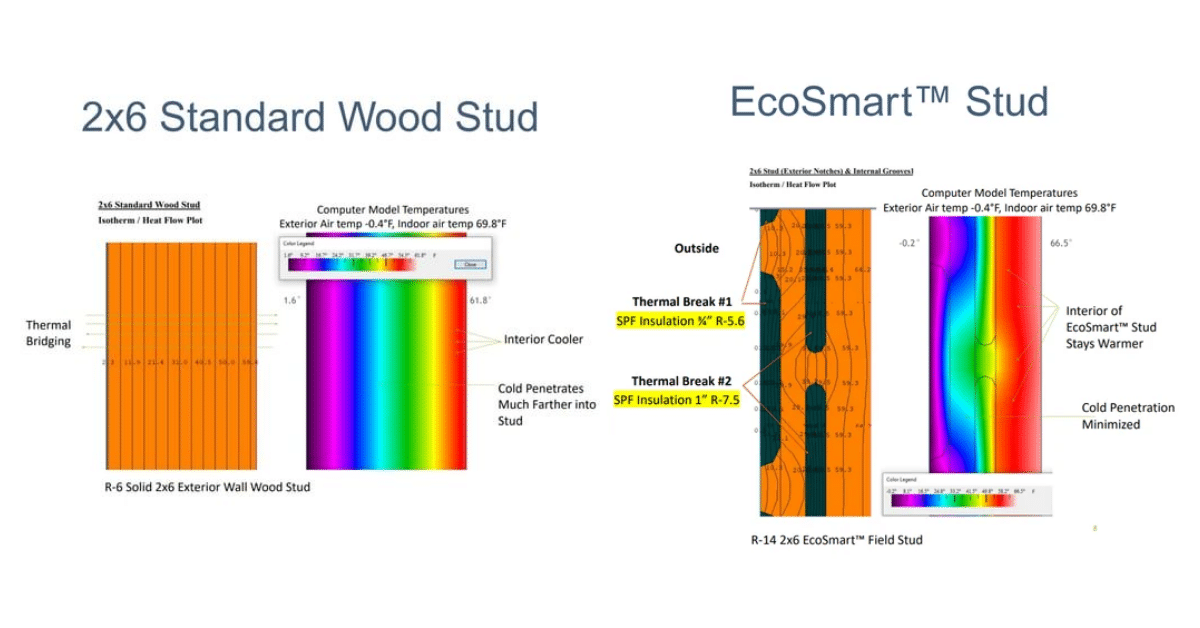

EcoSmart™ Studs stand out with their unique feature: built-in thermal breaks. These thermal breaks get filled with insulation, transforming EcoSmart™ Studs into insulated framing studs. This innovative design achieves the goal of Exterior Continuous Insulation, increasing the R-value of the framing and reducing thermal bridging energy losses through the exterior wall studs.

The EcoSmart™ Stud wall system is highly effective in achieving a higher R-value of the framing stud and chamber. In fact, the effective R-value of the EcoSmart™ Stud wall system is equivalent to or even higher than that of the Exterior Continuous Insulation wall systems. This is made possible by the Flash and Fill insulation, a combination of 2 lb. closed-cell spray foam (Flash) and blown-in (Fill) insulation.

It’s worth noting that while the bottom and top plates lack extra insulation, this only accounts for 4.4% of the heated wall area. In the grand scheme of things, this doesn’t significantly impact the performance comparison between the EcoSmart™ Stud and Exterior Continuous Insulation wall systems.

Read the full breakdown of R-value performance and plate coverage.

Cost Savings with Smarter Framing

Cost is the top concern for builders. This is where the EcoSmart™ Stud wall system really stands out. The current calculated upgrade cost in Minnesota for the 2×6 EcoSmart™ Stud wall system with the required R-27 Flash & Fill insulation mix is $1 per square ft for above grade walls. Compared to an estimated $4.90 per square ft for an Exterior Continuous Insulation wall system. Both wall systems have similar effective R-value/U factors for the exterior wall. Cost is the big difference.

For example, the average 2300 sq ft house with an Exterior Continuous Insulation wall would run an extra $11,270 for the Exterior Continuous Insulation wall system. The 2×6 EcoSmart™ Stud wall system adds only an extra $2,300, leaving $8,970 to be spent on the other needed insulation upgrades.

With 1.01 million Single homes built in the US in 2024, that’s potentially billions of dollars in cost savings for American Consumers when buying a new home per year. That’s before energy savings. These savings can be redirected to other energy upgrades, such as solar panels, bringing Net Zero homes within reach for more homeowners.

Explore the cost comparison in detail.

Added Strength at No Extra Cost

Thermally broken studs paired with Flash and Fill insulation do more than just insulate. The 2 lb. closed cell spray foam is needed to get the required insulation values for the exterior wall. The free bonus is the added racking strength. 2 lb. closed cell spray foam is not only great insulation, it is a 2-part polyurethane glue. Now the exterior wall system is glued and nailed together for far superior racking strength. Exterior Continuous Insulation wall systems have no added strength, just added insulation value.

A better built home stays standing longer in extreme weather events!

See why resilience matters with thermally broken framing.

Flash and Fill Insulation = Less Waste

EcoSmart™ Stud wall systems, utilizing Flash and Fill insulation, are a testament to our commitment to sustainability. With significantly less waste and no trimmed-off ridged foam panel leftovers, our system not only saves contractors money but also reduces the burden on landfills. By choosing EcoSmart™ Studs, you’re not just making a cost-effective choice, but also a responsible one for the environment.

Furthermore, EcoSmart™ Studs significantly reduce the time spent on cleaning up drilling waste from solid studs by the mechanical trades. The EcoSmart™ stud has the wood removed at the production facility and repurposed for another product, saving valuable time and resources.

Read more about how thermally broken framing reduces embodied carbon and waste.

Thermal Breaks in the Bottom and Top Plates is Always an Option

Thermally broken plates are always an option with the EcoSmart™ Stud wall systems.

For the 2×6 wall system it’s very simple to remove another 1.46% from the equation by using a 2×4 as the bottom top plate. That gives 2” of room for SPF to fill in and give that section an R-19 rating plus it seals the space between the 2 top plates against air infiltration.

The 2×8 wall system the bottom plate can be thermally broken removing another 1.46% from the equation leaving only 1.46% of the total wall system to straight through thermal bridging. Granted with a 2×8 plate, that would have an R-value of R-8.5 to start with, over an R-11 with all insulation elements added in for the exterior wall.

Thermally broken framing with these small upgrades maximize energy savings.

Cost is the Main Issue for Continuous Insulation

Cost is the Main Issue for Continuous Insulation

Don’t take this article the wrong way. Exterior Continuous Insulation is not a bad way to insulate a home, it’s just really expensive and complicated. Plus there is no structural reinforcement and there is extra insulation waste.

Realistically we just need to get thermal bridging in a home to a manageable level the most cost-effective way. Solar electrical production costs for a Net Zero home have dropped dramatically in the last 20 years.

If we can save $9,000 in insulation costs and put that money to towards the $15,000 solar array it makes financial sense. If the difference in the size of that array is 1 extra solar panel to offset the loss of insulation efficiency it makes even more sense. It’s a better allotment of the customers’ finite resources when building a new home.

Cost is Key to get to Net Zero

EcoSmart™ Studs and Flash and Fill insulation offer a simple, high-performing, and affordable path to Net Zero homes. Exterior continuous insulation and rigid foam panels drive up costs, waste, and complexity.

Let’s rethink how we build. Let’s replace outdated insulation methods with smarter framing and thermal strategies that work for builders.